logistics visualization, the key to addressing supply chain disruptions

, in today's life, we have become accustomed to the "visual" delivery of express delivery and take-out, and we no longer need to call the merchants to inquire and urge them. In recent years, the "visualization" in the field of daily logistics has increased the transparency and trust between customers and merchants, improved customer satisfaction, reduced uncertainty, reduced customer complaints, and created a win-win situation for all.

in the global supply chain, there are more and more new participants, more complex processes, and more unpredictable political, economic and social variables that appear every day. These variables need to be dealt with and make decisions faster. Logistics companies play a key role in ensuring the smooth flow of goods and services, and visibility has become an important key to success in the modern logistics environment.

Logistics Visibility-The Top Supply Chain Challenge]

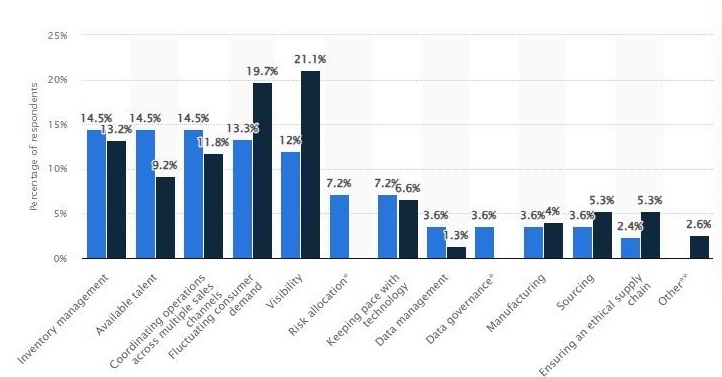

as early as 2018, the German statistical agency Statista launched a survey of global supply chain executives and concluded that the primary challenge in the logistics market is "visibility"-in the figure below, the "visibility" challenge accounted for 12% in 2017 and rose to 21.1 in 2018, ranking first:

What are the biggest challenges in the supply chain? (Source: Statista)

in response to this demand, front-line logistics companies are beginning to adopt new technologies-first barcode, RFID and GPS, and more recently the Internet of Things (IoT), blockchain, artificial intelligence (AI) and big data-to improve visibility at the heart of modern supply chain management.

[Internet of Things (IoT) Technology]]

By collecting and transmitting in real time the location, status and environmental data of items required for logistics activities such as trucks, pallets, containers, etc., all participants can easily monitor, track and manage logistics activities. For example, the IoT module added to the logistics system of a large vehicle can link each container with a digital logistics management and control system to monitor information such as location, speed, mileage, and information such as fuel consumption, driving routes, and performance data, including possible Fire, intrusion detection, and anti-theft alarms, so as to achieve efficient and safe workflows.

For cold chain products affected by the external environment, IoT technology can also monitor the temperature and humidity of all processes from production and storage to delivery to customers to check for abnormalities

Big Data and Artificial Intelligence]

in the world's closely linked supply chain, a large amount of data is generated all the time. This data is collected, analyzed and used to improve visibility.

For example, historical sales data, market trends, weather information, and other factors can be used to predict inventory demand for a particular product or region. By combining data from IoT sensors and GPS tracking with data on road conditions, traffic, and demand, various data can be analyzed and predicted in real time, such as predicting travel time, calculating optimal transportation routes, and redeploying vehicles to minimize transportation costs and time. In addition, big data and artificial intelligence can also be used to predict when logistics equipment and vehicles will need to be maintained and repositioned to improve responsiveness to emergencies.

Cloud System]

cloud system allows logistics companies to share their data and visibility with stakeholders such as shippers, carriers, consignees, etc., not only to store information, but also to allow all participants to view all data in real time and carry out relevant links. Management operations, everyone shares tasks and makes decisions quickly.

At the same time, there is also a need to provide protection for data and visibility. Major cloud service providers have established comprehensive data security systems that enable logistics companies to minimize the risk of data loss, damage and tampering, thereby increasing the visibility of logistics Trust. In addition, based on the flexibility and scalability of the service, it can be customized for all participants including various devices, operating systems and applications.

Transportation Management System (TMS)]]

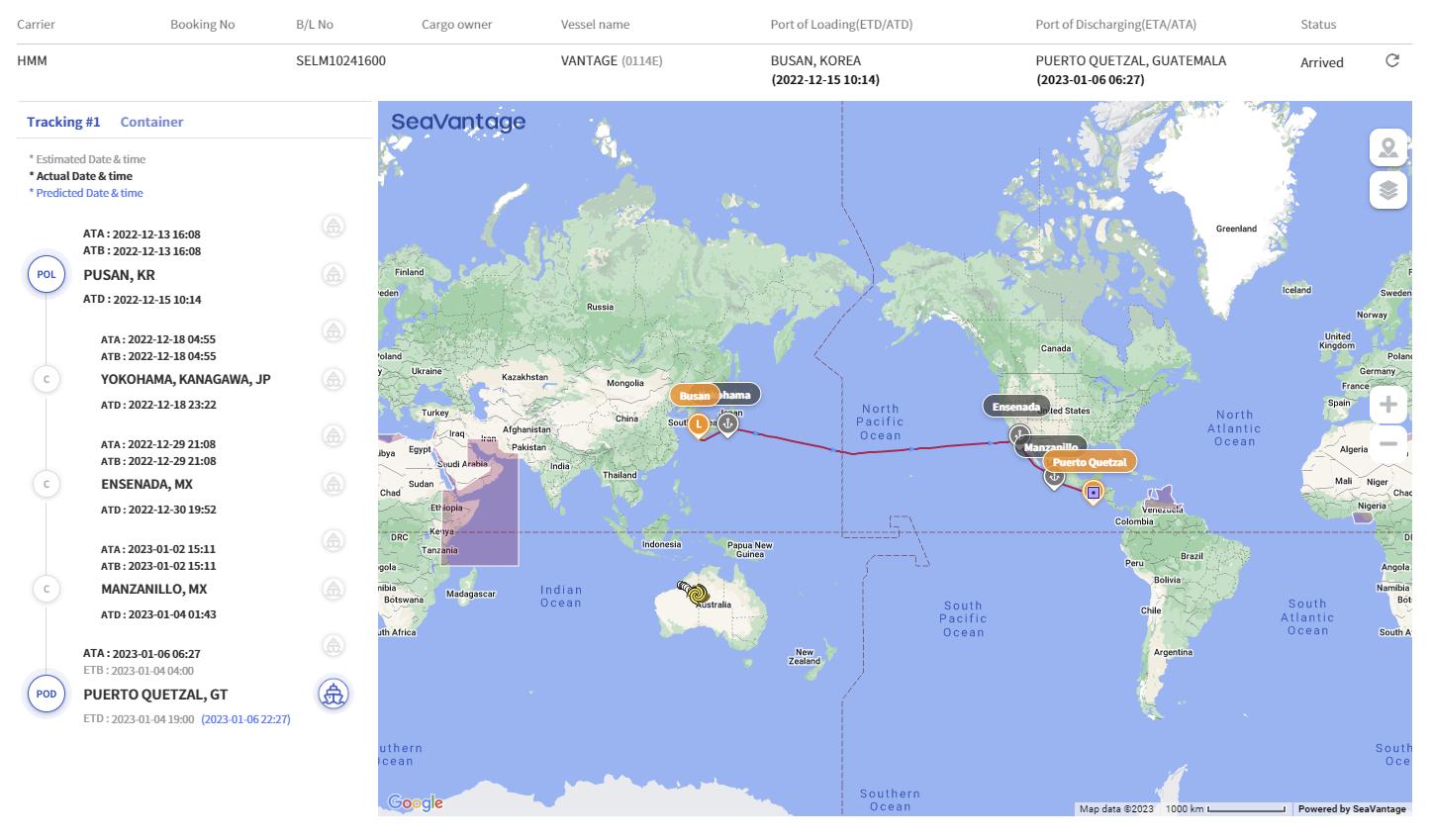

TMS is the most widely used visualization tool in the logistics industry. The logistics company provides applications that allow users to plan, execute and monitor transportation activities, including cargo loading and tracking, fleet management, route optimization and carrier selection, through a simplified transportation operation system, while improving efficiency and reducing costs.

The above is the logistics control interface of Cello Square. However, logistics companies such as BCLOG (Large Vehicle), which focus on subdivision (international transportation of photovoltaic products), choose to develop a more suitable digital logistics management and control platform, and provide more refined and efficient visual management and control services from product delivery to order delivery according to the unique needs of the industry.

[Warehouse Management System (WMS)]]

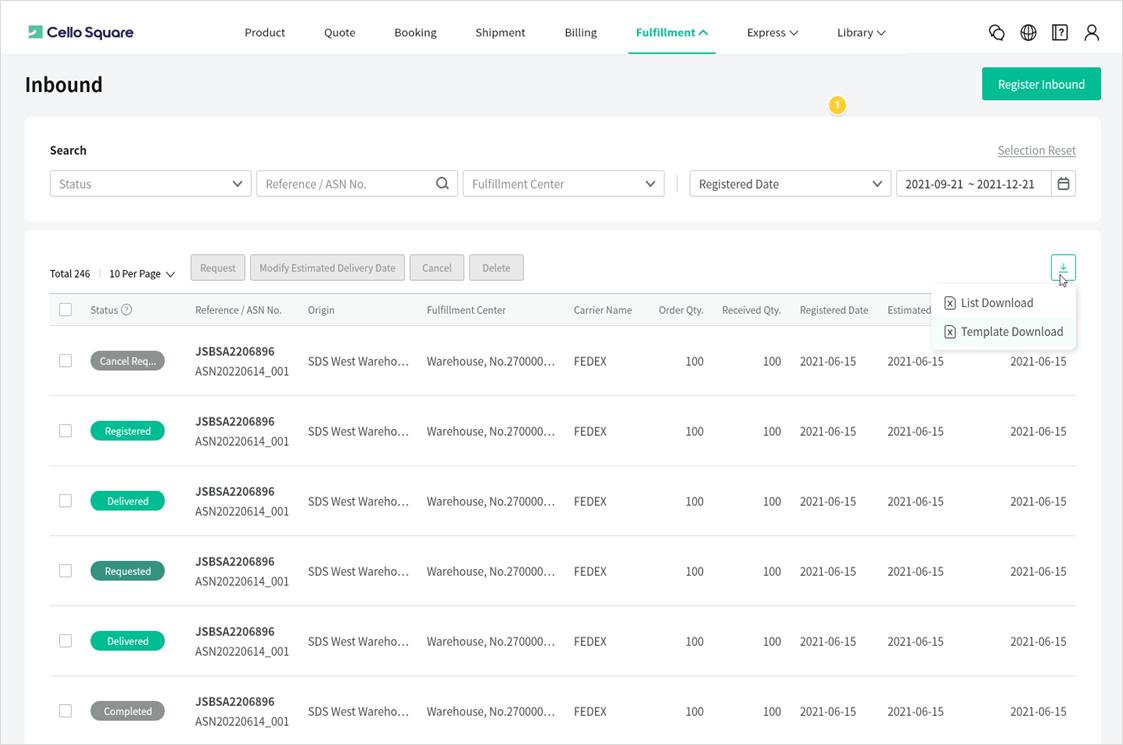

WMS is a system that manages the entire process from the entry of goods into a warehouse or fulfillment center until departure. In recent years, due to the explosive growth of e-commerce, the demand for fulfillment has increased, and the need for real-time response has become more important. WMS simplifies operations through real-time inventory management, incoming and outgoing management, and optimization of storage space, thereby improving logistics visibility, while increasing the productivity of warehouse employees and customer satisfaction.

Warehouse Management> Warehouse Management System Diagram

In the logistics industry, the visualization of "end-to-end supply chain" requires seamless connection between transportation management system (TMS), warehouse management system (WMS) and enterprise resource planning (ERP).

[LogisticsvisualizationImpact]]

improved logistics visualization has a positive impact not only on logistics companies, but also on other players such as shippers in the supply chain. For shippers, an accurate understanding of inventory can reduce excess inventory and speed up inventory turnover, thereby reducing costs. It can also reduce transportation costs and maximize efficiency through real-time route monitoring and optimization.

For customers, they can adjust their schedule according to the transportation status to adapt to the arrival time of the product and prepare in advance. Companies can also respond quickly to problems in transit and enhance trust by informing customers of the exact cause of product damage.

logistics visualization enables shippers to seamlessly collaborate by sharing data with all participants, preventing information discrepancies. If something goes wrong, all information is shared in order to build trust to solve the problem and plan for the future. In addition, it can also jointly predict and discuss weather events, peak demand periods, etc., and develop plans to reduce costs and improve customer service.

so, logistics visualization can prevent supply chain disruptions and reduce maintenance costs.

the advent of the era of free trade, many large companies focus on building global supply chains,However, from the neo-crown epidemic to the Russia-Ukraine war to the recent outbreak of the Israeli-Palestinian conflict, uncertainties have had an unprecedented impact on supply chains, and of course the U. S.-China trade conflict and extreme weather, which have led to delays and disruptions in production and supply in some regions, reduced competitiveness, and a significant decline in customer satisfaction and trust.

In response, many organizations are shifting their supply chains from JIT(Just In Time) to a Just In Case (JIC) approach based on logistics visibility-a way to maintain sufficient inventory to ensure stable production in an uncertain environment. Under adverse circumstances, JIC enables customer service levels to be maintained, thereby increasing customer satisfaction and business confidence.

experts believe that combining the advantages of JIT and JIC will be the key to future supply chain management, and logistics visualization is expected to play a key role in the establishment of new supply chains, enabling companies to quickly identify product movements, inventory status and supply chain status in real time. In particular, carriers will be able to make more flexible decisions in the face of uncertainty, improving customer satisfaction and competitiveness by optimizing inventory management and production planning.

-- BCL class notes on a large car--

Logistics Visualization]

refers to the visual display of information in the process of logistics transportation through charts, maps, data, etc., so that people can understand the status of cargo transportation in real time, track logistics information, and analyze logistics data.

logistics visualization lies in:

Improve the efficiency of logistics management: Through real-time monitoring and analysis of information in the process of logistics and transportation, enterprises can more accurately grasp the location, status and transportation progress of goods, so as to adjust the transportation plan in time and improve the efficiency of logistics management.

Enhance logistics safety: Logistics visualization can help companies understand the transportation status of goods in real time, find abnormal situations in time, and improve the safety of goods through remote monitoring and control equipment.

Improve customer experience: Through logistics visualization, customers can understand the transportation status of goods in real time, improve the traceability of goods, and improve customer experience.

Reduce logistics costs: Through logistics visualization, companies can more accurately grasp the information in the logistics and transportation process, thereby optimizing transportation plans and reducing logistics costs.

support decision analysis: logistics visualization can help enterprises understand various data in the process of logistics and transportation in real time, provide data support for decision-making, and improve the accuracy and scientificity of decision-making.

Therefore, logistics visualization is an important means of modern logistics management, which is of great significance for improving logistics efficiency, reducing logistics costs and improving cargo safety.

Supply Chain Disruption]

refers to the failure or stagnation of a link in the supply chain due to various reasons in the supply chain management process, which affects the normal operation of the entire supply chain. The causes of supply chain disruptions may include natural disasters, political turmoil, corporate bankruptcies, production line failures, and logistics and transportation problems. Supply chain disruptions often lead to production delays, higher costs, customer service, and may even have a long-term impact on a company's reputation and competitiveness. Therefore, supply chain management is very important for enterprises, through the implementation of effective supply chain management strategy, enterprises can better deal with the risk of supply chain interruption, to ensure the stable operation of the supply chain.